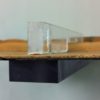

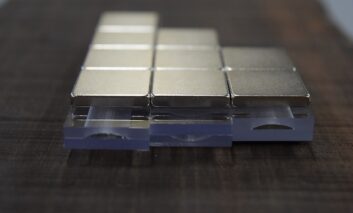

These feather-weight (less than .8g), thin (.055), super strong cleats are the heart of this new system. Combined with installation cauls and strong magnets, they allow you to glue both the crack and the cleat in one operation. Once everything is located and aligned, the cleat can be installed perfectly in less than 60 seconds, making hide glue a viable option. The grain is oriented at an angle (matching that of prewar tone bars), which is about the only thing they have in common with their earlier predecessors, the diamond and disk cleats. If you ever need to uninstall the cleat, it can quickly be removed (if glued with hide glue, other glues will take longer) by laying a warm damp sponge on it. Within a few minutes, you’ll be able to lift the cleat out. Any residual hide glue can be removed with warm water and a small sponge.

Top Crack Corrector

A new system that combines modern technology with old school materials

Price: